Product Structure and Working Principles

Reflective picket pockets are engineered with a multi-layer design to enhance functionality:

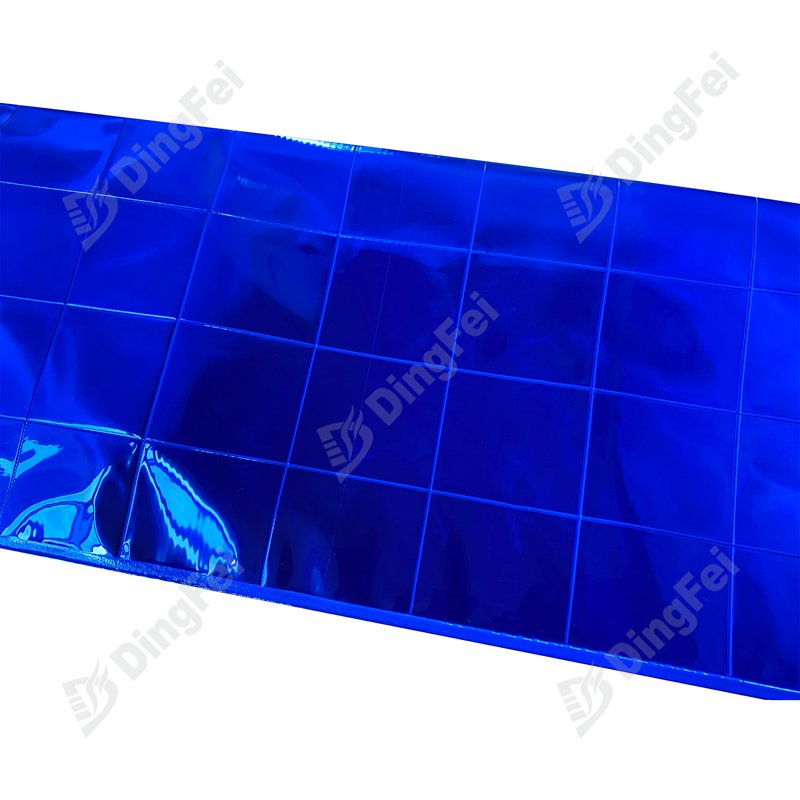

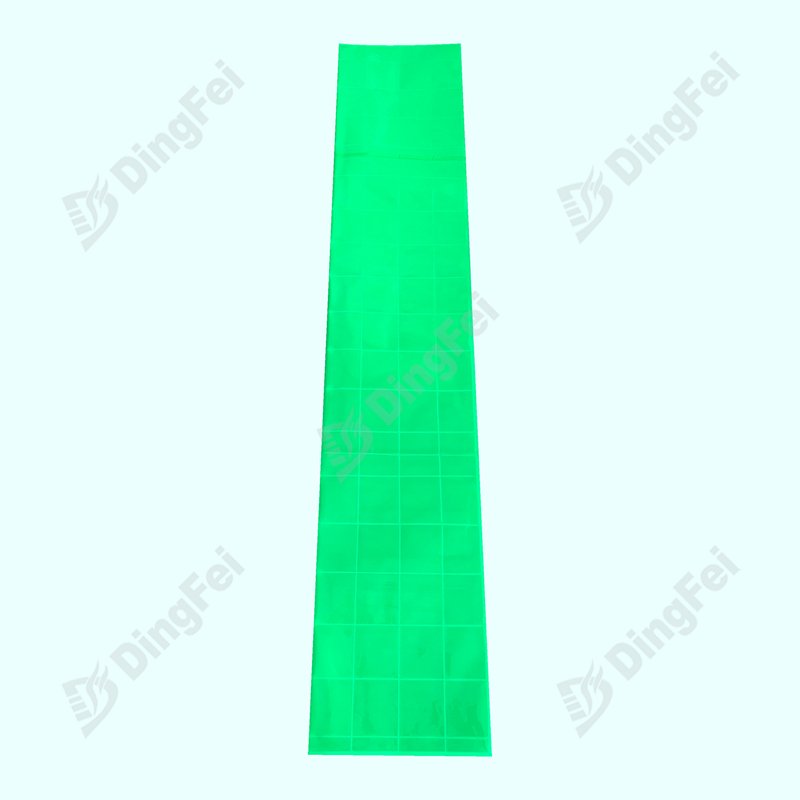

Base Material: Made of flexible yet durable PVC, these pockets are weatherproof, lightweight, and resilient to mechanical stress.

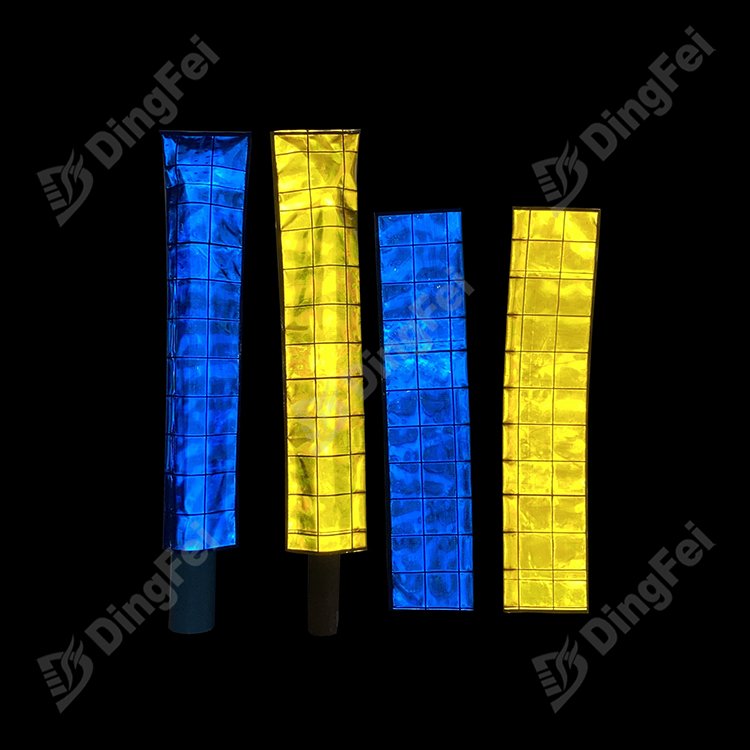

Reflective Layer: Incorporates micro-prismatic or glass-bead technology for superior light reflection. The micro-prisms are arranged to refract light back to its source, ensuring high visibility at night or in low-light conditions.

Adhesive or Welded Seams: Ensures secure attachment to bollards, posts, or traffic barriers without shifting or peeling.

Protective Coating: Includes UV-resistant and anti-moisture coatings that shield the reflective layer from environmental degradation.

This layered structure maximizes visibility, even in adverse conditions like fog, rain, or dusty environments, ensuring compliance with safety standards.

Customization Options: Tailored for Your Needs

Reflective picket pockets can be customized to suit specific projects or branding needs:

Sizes and Shapes: Standard sizes range from 200mm x 1000mm to 300mm x 1500mm. Custom dimensions and shapes can be tailored to fit unique equipment or barriers.

Printed Designs: Logos, text, or directional symbols can be printed directly on the reflective surface using UV-stable inks. This feature supports personalized safety messages or corporate branding.

Reflective Colors: Choose from high-visibility colors such as red, white, orange, yellow, green, and blue, each aligning with safety regulations for different applications.

Reflectivity Levels: Options include Engineering Grade (EG), High-Intensity Prismatic (HIP), and Diamond Grade (DG), providing varying levels of brightness and visibility.

Product Benefits: Enhanced Safety and Efficiency

Investing in reflective picket pockets delivers multiple advantages:

Increased Worker Safety: Ensures clear demarcation of hazardous zones, reducing accidents.

Improved Traffic Management: Effective in controlling vehicular and pedestrian movement in work zones.

Cost-Effective: Long-lasting materials reduce replacement frequency, lowering operational costs.

Versatile Applications: Suitable for mining operations, construction sites, highways, and warehouses.

Sustainability: Recyclable materials support environmentally responsible practices.

Proper Usage Guidelines

For optimal performance, follow these usage instructions:

Attachment: Secure the picket pocket firmly onto the post or bollard using compatible clips or fasteners.

Positioning: Place at a height and angle that maximizes visibility from all directions.

Regular Inspections: Check for signs of wear, fading, or detachment to ensure consistent performance.

Maintenance Tips: Prolong the Lifespan

Proper care can extend the life of reflective picket pockets significantly:

Cleaning: Use mild soap and water to clean dirt or grease. Avoid abrasive chemicals that can damage the reflective surface.

Storage: When not in use, store in a cool, dry place away from direct sunlight.

Repair: Small scratches or cracks can be sealed with transparent adhesive patches to maintain reflectivity.

Technical Specifications Table

|

Feature |

Specification |

|

Material |

Premium PVC with micro-prismatic reflective film |

|

Reflective Grade |

EG, HIP, DG |

|

Color Options |

Red, white, orange, yellow, green, blue |

|

Printing Options |

UV-stable logo/text printing |

|

Temperature Resistance |

-20°C to 65°C |

|

Standard Dimensions |

200mm x 1000mm (custom sizes available) |

|

Lifespan |

5-8 years in outdoor conditions |

|

Standards Compliance |

Australian Standard AS/NZS 1906.1:2017 |

As a trusted manufacturer of reflective safety solutions, we provide high-quality picket pockets tailored to your specific requirements. From cutting-edge materials to compliance with Australian safety standards, our factory ensures unparalleled quality and reliability. Contact us to explore customized designs or receive expert guidance on your safety projects.