Reflective Danger Mines Triangle Signs are essential for ensuring safety in mining areas, providing visible warnings of potential hazards, even in low-light conditions. These signs combine high-performance reflective materials with durable construction, ensuring clear communication and compliance with safety regulations. This guide explains the features, benefits, and industry standards for these critical safety tools.

Key Features of Reflective Danger Mines Triangle Signs

Reflective Danger Mines Triangle Signs are typically constructed from highly durable materials like PVC or aluminum. These signs are designed to last in harsh environments while offering high reflectivity for visibility. Here are some key features:

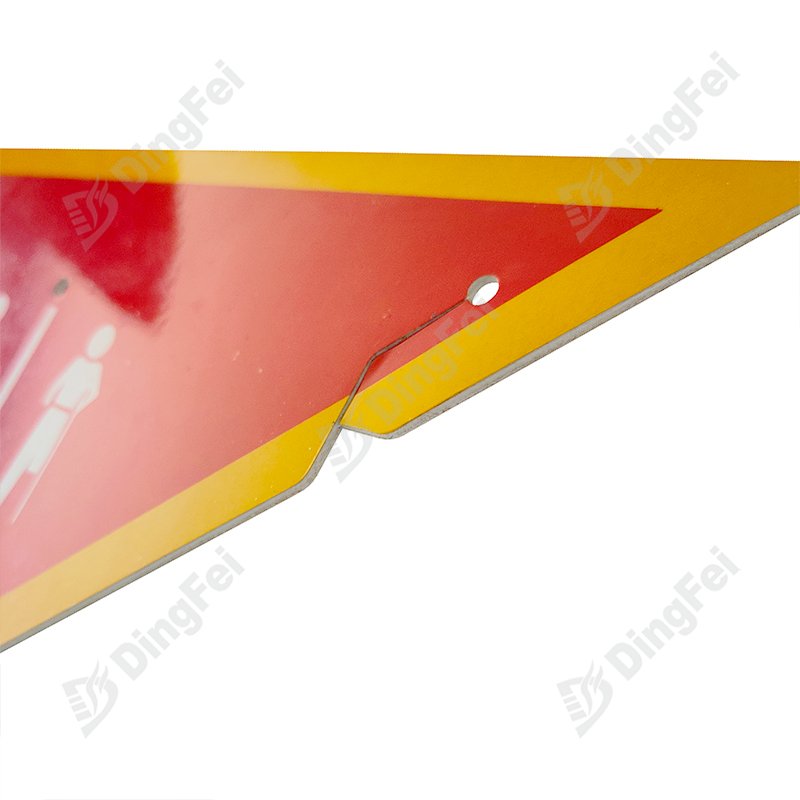

Durability: The most common materials used for these signs include 3mm PVC, aluminum, and HDPE (High-Density Polyethylene), ensuring they withstand harsh conditions such as exposure to UV rays, moisture, and chemicals. For example, aluminum signs are highly resistant to corrosion and can last for many years under extreme weather conditions.

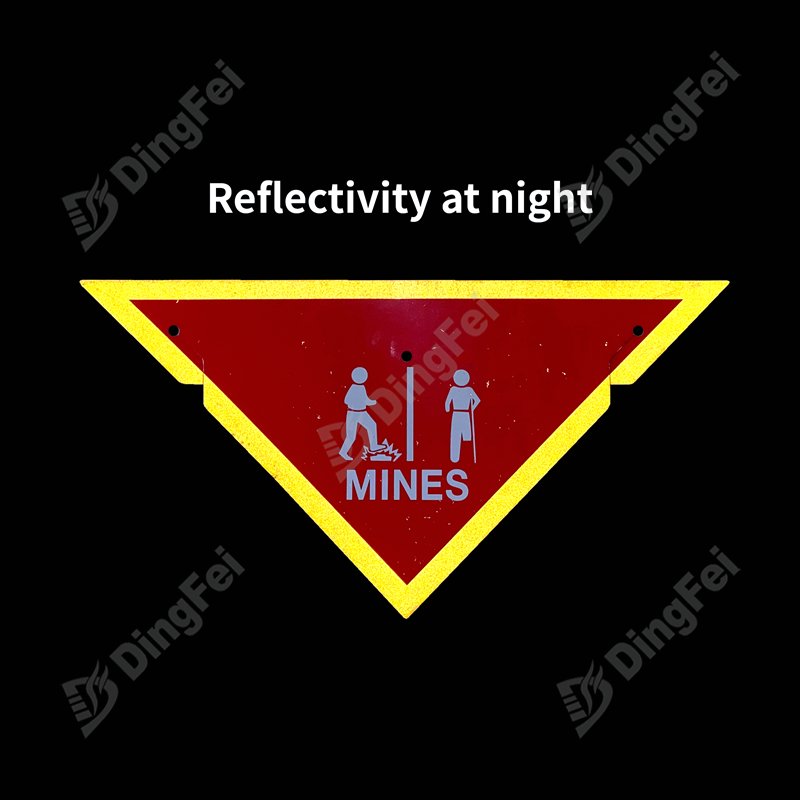

Reflective Technology: These signs use reflective materials like Diamond Grade, or Engineering Grade Reflective Sheeting, which are known for their high reflectivity, allowing the signs to remain visible from up to 1,000 meters away at night. This ensures they are seen from a distance in poor visibility conditions, such as fog, rain, or darkness.

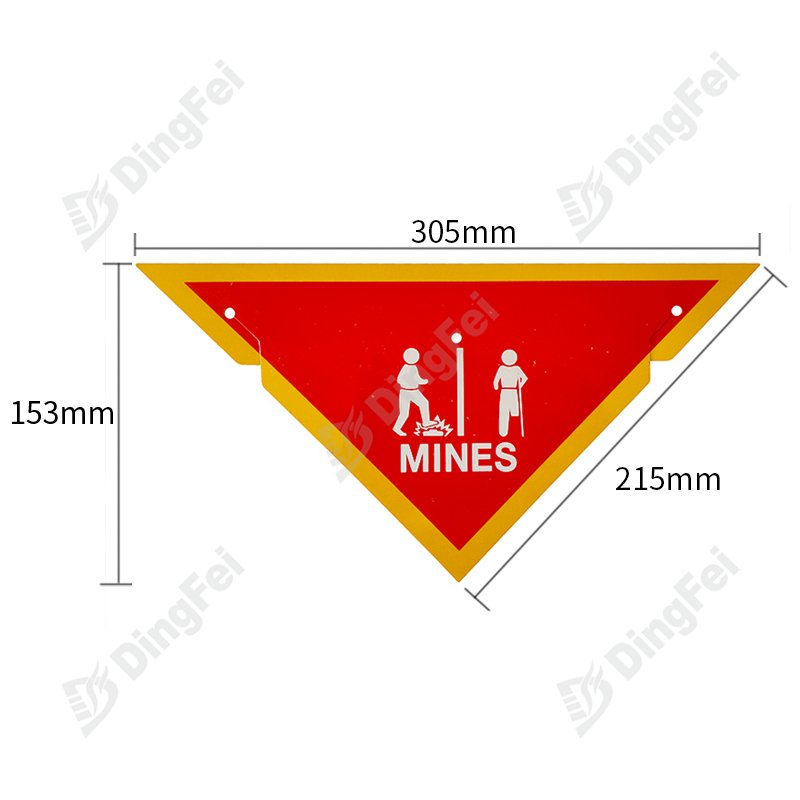

Variety of Sizes and Designs: These signs come in a range of sizes, typically from 300mm to 900mm in diameter. Custom sizes can also be requested to fit specific needs depending on the mine’s layout. The signs can be designed with standard triangle or custom formats to ensure clarity.

Compliance with International Standards: Reflective Danger Mines Triangle Signs comply with safety standards such as E/ECE/324, Article 6.16, and ISO 7010, ensuring the visibility and clarity of the warning signs, which is required to meet local and international safety regulations.

Why Reflective Danger Mines Triangle Signs Are Crucial for Safety

In mining environments, clear and visible warnings are critical to preventing accidents and ensuring worker safety. Reflective Danger Mines Triangle Signs help to:

Enhance visibility: In mining zones where visibility is often low, whether due to dust, fog, or nighttime, these reflective signs provide high visibility for workers and visitors.Direct personnel to hazardous areas, guiding them to avoid danger zones such as blasting zones, unstable ground, or toxic material areas.

Ensure compliance: Regulatory bodies in mining require that hazard areas are clearly marked, and using compliant reflective signs helps meet these requirements, preventing potential fines or operational delays.

Product Specification Table

|

Parameter |

Specification |

|

Material |

3mm PVC, Aluminum, HDPE (High-Density Polyethylene) |

|

Reflective Technology |

Diamond Grade, Engineering Grade Reflective Sheeting |

|

Visibility Range |

Up to 1,000 meters in low-light or nighttime conditions |

|

Standard Sizes |

300mm to 900mm diameter; customizable sizes available |

|

Durability |

7–10 years under normal mining conditions |

|

Weather Resistance |

Resistant to UV rays, moisture, temperature extremes, and chemicals |

|

Compliance Standards |

E/ECE/324, Article 6.16; ISO 7010 |

|

Symbol Design |

Universal warning triangle with hazard symbols |

|

Reflectivity Level |

Minimum 50 cd/lux to meet safety visibility requirements |

|

Applications |

Blasting zones, unstable ground, hazardous material zones |

Reflective Danger Mines Triangle Signs meet the European Union's mining safety standards, specifically the E/ECE/324 and Article 6.16 regulations. These regulations are designed to ensure that mine hazard signs provide sufficient visibility and clarity in hazardous environments. Key compliance factors include:

Reflectivity: Signs must achieve a certain level of reflectivity, typically a minimum of 50 cd/lux (candela per lux), to be visible from a distance of up to 1,000 meters in low light conditions.

Materials and Durability: The materials used must be resistant to environmental factors like UV rays, moisture, and temperature extremes. This ensures that the signs remain legible over time despite the wear and tear of mining environments.

Clear and Recognizable Symbols: The signs must use universally understood symbols, such as the warning triangle with a hazard symbol, ensuring that all workers, regardless of language, can quickly understand the danger.

These reflective signs are used in various mining scenarios to protect workers and visitors:

Blasting zones: To warn of explosive activities, ensuring workers stay a safe distance away.

Unstable ground: To alert workers of areas prone to landslides or ground collapse.

Hazardous material zones: To mark areas where dangerous chemicals or other hazardous materials are stored or processed.

Benefits of High-Quality Reflective Signs

By using high-quality reflective Danger Mines Triangle Signs, companies can achieve the following benefits:

Increased Safety: Reflective signs ensure that potential hazards are visible and clearly marked, reducing the risk of accidents.

Long-lasting Durability: Made with industrial-strength materials, these signs are built to last for up to 7-10 years under normal conditions, even in harsh mining environments.

Cost-effectiveness: While these signs may have a higher upfront cost, their durability and long lifespan make them a cost-effective solution in the long run.

Conclusion: The Importance of Reflective Danger Mines Triangle Signs

Reflective Danger Mines Triangle Signs are a vital tool in mining safety, providing essential hazard warnings that are highly visible, durable, and compliant with international safety standards. Whether marking blasting zones, unstable ground, or hazardous material areas, these signs help ensure that mining environments are safer for workers. By investing in high-quality reflective mine warning signs, mining companies not only meet regulatory requirements but also protect their workforce from potential hazards.